Product Classification

-

-

-

Efficient wear-resistant grading sieve plate 750*1000*40 mesh: 35*40

-

Yellow High-resistance Polyurethane screen panel for Mining industry

-

300mm*600mm*35mm Yellow Polyurethane screen panel Opening size:6mm

-

300mm*600mm*35mm Yellow Polyurethane screen panel Opening size:63mm

-

610mm*610mm*47mm Polyurethane and stainless steel vibrating screen mesh sieve plates

-

Ore PU high-frequency polyurethane sieving plate for vibrating screen in Mining

-

610mm*305mm*78mm Polyurethane screen panel for Mining machine

-

High-performance and wear-resistance abrasionCustomized polyurethane screen panel

-

High polyurethane screen panel 822mm*696mm*60mm,aperture size:4.85mm*15mm

2270mm*355mm*4mm Yellow flip-flow screen panel

Category:

2270mm*355mm*4mm Yellow flip-flow screen panel

Summary:

Keywords:

Polyurethane Elastomer

2270mm*355mm*4mm Yellow flip-flow screen panel

Polyurethane Screen Panel

Product Introduction

Polyurethane is a new type of polymer composite material and belongs to high-tech products,its nature between plastic and rubber but its performance is much better than the two, is an ideal material to replace them.

PU screen panel is made of polyurethane materials. It mainly usedfor miningmineral processing,grading,dehydration and other screening machines replace metal sieve(mesh)of a new product.

Mainly used in coal, iron ore, copper, gold and other ores grading, screening, dewatering and other places. It can separate and screen almost all of materials from coarse stones to fine materials and ideal for both dry and wet materials.

Specifications

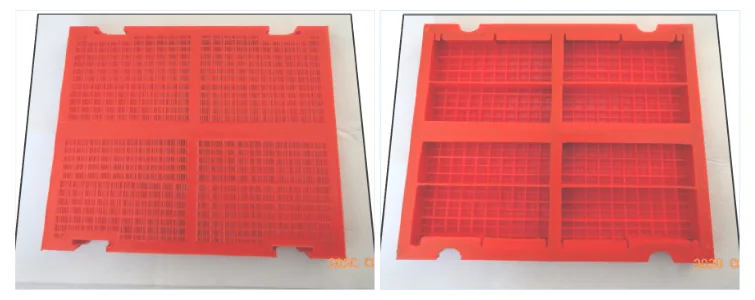

Material: polyurethane material and steel frame.

Cut point: 0.5mm

Thickness: 25mm - 60mm.

Hole type: square, rectangular, round and other types are available.

Hole size: 2.5mm - 140mm.

Panel width: customed

Panel length: customed

Hook type: metal or polyurethane.

Hook direction: transverse or longitudinal.

Color: red, yellow, and other colors you want.

Features:

Polyurethane materials for wear resistance. Self-cleaning apertures reducing pegging and blinding. Wide range apertures suit most applications. Various panel sizes to suit all vibrating screens. Different connection type for easy installation and replacement. High screening performance. Low noise. Long service life and durable

Applications:

The modular polyurethane screen panel can fit various vibrating screens and widely used in various applications.

Steel plants.

Mining industry.

Cement plants.

Mineral beneficiation industry.

Power plants.

Coal washing.

Sand, gravel separating and screening.

Product Advantages

1.It has good wear resistance and long service life. Its wear resistance is 3-5 times of that of steel screen panel and more than 5 times of that of ordinary rubber screen panel.

2.The maintenance workload is small, the polyurethane screen panel is not easy to be damaged, and the service life is long, so the maintenance workload and the loss of shutdown maintenance can be greatly reduced.

3.The total cost is low. Although the one-time investment of polyurethane screen panel of the same specification (area) is higher than that of stainless steel screen panel (about 2 times), the service life of polyurethane screen panel is 3-5 times of that of stainless steel screen panel, and the maintenance and replacement times are less, so the total cost is not high, and it is economical.

4.With good moisture resistance, it can work under the condition of water as the medium, and in the case of water, oil and other media, the friction coefficient between polyurethane and materials is reduced, which is more conducive to screening, improving screening efficiency, and avoiding the adhesion of wet particles. At the same time, due to the reduction of friction coefficient, the wear is reduced, and the service life is improved.

5.Corrosion resistant, nonflammable, nontoxic and tasteless.

6.Due to the reasonable design of the screen hole and the unique manufacturing process of the screen panel, the particles of the limit size will not block the screen hole.

7.The utility model has the advantages of good vibration absorption performance and strong noise elimination ability, which can reduce noise, and make the objects on the screen not easy to be broken in the process of vibration.

8.Due to the characteristics of polyurethane secondary vibration, polyurethane screen panel has self-cleaning function, so the screening efficiency is high.

9.The polyurethane is energy saving and consumption reduction, and small proportion.It is much lighter than the same size of steel screen, thus it reduce the load of screen machine, save power consumption, and prolong the life of screen machine.

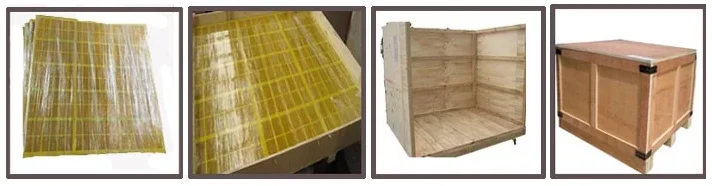

Packing & Shipping

| Packing of The Polyurethane Screen Panel | |

| 1 | The goods are covered by special protective film to avoid the damage from friction during tansportation. |

| 2 | The loaded in strong wooden pallet and wooden case. |

| 3 | We can also do according to your requirement. |

Our Services

1. Our R&D team: we have our own professional research and development team;

2. Unique product prescription: Our prescription greatly improve the quality of our products;

3. Wide range of application: We have established long business relationship with many famous international companies

4. Production capacity: We have a big factory, so our production capacity is strong.

5. Short delivery time: All products you want can be completed within short time.

FAQ

Q: Are the samples free of charge?

A:Yes, all samples are free of charge.But if you need the sample which is bigger than our prepared sample,a little of fee will be needed.And, the sample fee will be returned as soon as the order placed.

Q: How about the payment terms?

A:30% in advance as deposit by TT,the balance payment before the shipment;

Q: What is the delivery time?

A: It is according to your quantity,normally 10 to 20 days;

Q: After sale service.

A: Every product will be inspected strictly before delivery. We'll in charge of all losses if there is any quality problem.

Previous

none

Next