The role of polyurethane sieve plate in the desulfurization system

2025-07-16

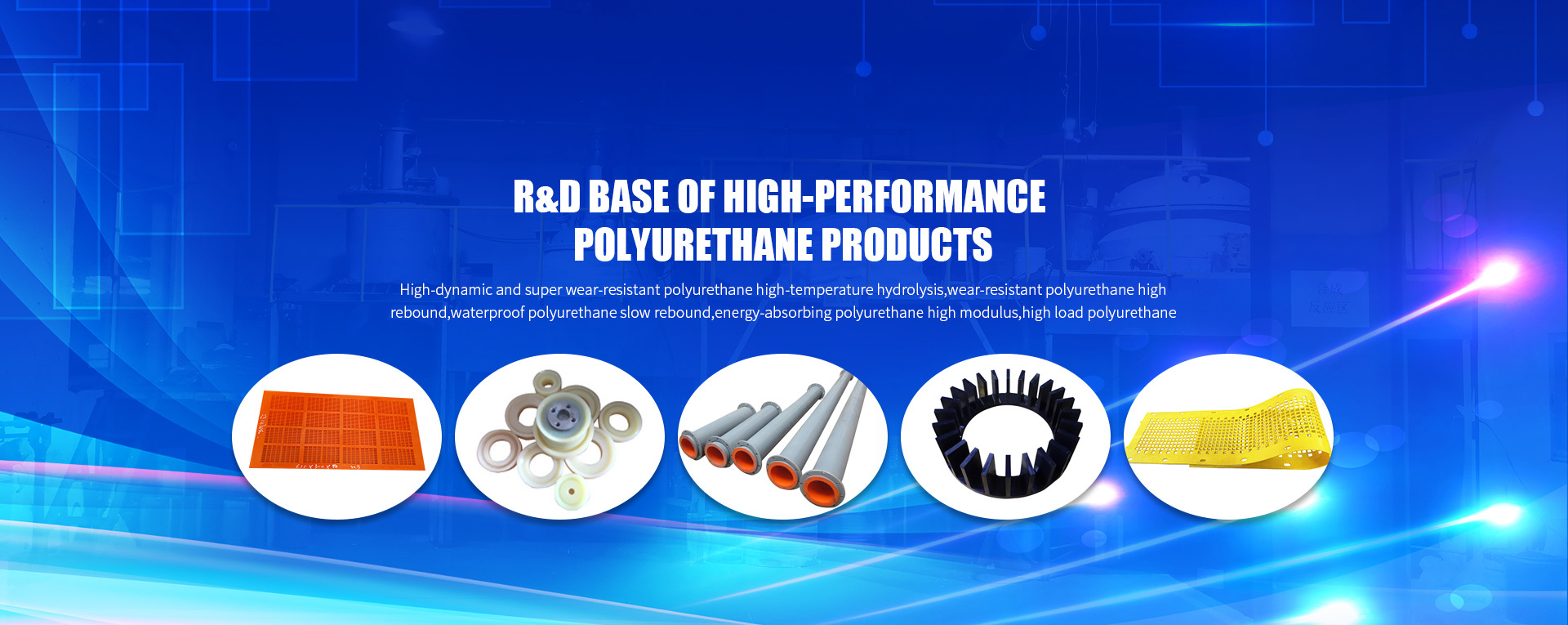

Basic properties of polyurethane sieve plates

Polyurethane sieve plates are sieve plates produced from polyureth as raw material, with a variety of excellent properties, such as water resistance, corrosion resistance, aging resistance, convenient replacement and maintenance, etc.3. These properties make the polyane sieve plate perform excellently in a variety of industrial applications, including desulfurization systems.

Specific role in the desulfurization system

1. Improve screening efficiency

The self-cleaning performance of the polyurethane sieve plate is good, it will not clog, so the screening efficiency is high. Its mesh angle is large (140°), which can effectively prevent the adhesion of wet fine particles, and is suitable for the screening of wet fine materials. In the desurization system, this helps to separate solid particles and liquids more effectively, improving the desulfurization efficiency.

2. High precision screening

The production process of theurethane sieve plate uses a casting molding process, with accurate pore size and high screening quality, and the particle size of the sieve residue can meet the user' requirements well. In the desulfurization process, precise screening can ensure the effective use of desulfurization agents and improve the desulfurization effect.

3 Long life and high load capacity

The service life of the polyurethane sieve plate is long and the load-bearing capacity is large. Its service life is 8-0 times that of ordinary metal sieve plates, 3 times that of stainless steel sieve plates, and 3.9 times that of natural rubber. In the desulfization system, this long life and high load-bearing capacity means a lower replacement frequency and maintenance cost, and improves the stability and reliability of the system.

4. Red noise and improve working environment

The noise of the polyurethane sieve plate is 5-20 dB lower than that of the metal sieve plate, which greatly reduces flying dust, making the production site have a quiet and clean working environment. In the desulfurization system, this not only benefits the health of the operators but also helps to noise pollution and improve the overall working environment.

5. Significant economic benefits

Although the price of the polyurethane sieve plate is higher than that of the metalieve, considering the screening efficiency, maintenance cost, service life and other factors, the comprehensive benefits of the polyurethane sieve surface are far superior to those of the metal s. In the desulfurization system, this economic benefit improvement can be reflected by reducing downtime and maintenance costs.

Conclusion

In summary, the polyurethane sieve plays an important role in the desulfurization system, including improving the screening efficiency, ensuring high precision screening, extending the service life of equipment, reducing noise and improving the working, and providing significant economic benefits. These properties make the polyurethane sieve plate an indispensable part of the desulfurization system

Keywords:

Related News

undefined